Why use CUTEK® Precoating Products?

CUTEK®: THE PROVEN PRE-OILING SOLUTION

CUTEK® has a 30-year track record as innovators in the timber protection and pre-oiling markets across five continents. CUTEK® timber oils are independently tested and proven to offer powerful, long-term protection and dimensional stability improvements that stand-up in the most extreme environments. Beyond the protection characteristics, CUTEK® timber oils enhance, rather than obscure, the natural grain and beauty of wood.

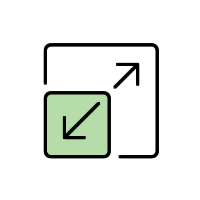

SUPERIOR PENETRATION WITH SELF-HEALING EFFECT

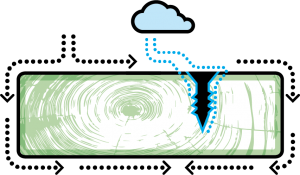

CUTEK® wood finishes work differently to traditional wood stain/wood oil/acrylic/urethane/natural oils/wood coating products in that CUTEK® protects your timber from the inside out. CUTEK® penetrates deeply into the wood core upon application, protecting it from the damaging effects of liquid and gas phase water, significantly increasing the service life of your timber. It does this by remaining PERMANENTLY MOBILE inside the wood, migrating to any cut or perforation with a self-healing action.

Many opposition products claim to be a penetrating oil finish; however, they often contain a mixture of solvents, polymers and cross-linking natural oils (such as linseed and tung oils) that penetrate only a few millimetres before drying to form an encapsulating type varnish. Because these coatings do not have a self-healing effect, once this varnish is exposed to the weather, water can quickly enter the core of the timber especially if it has been cut or perforated with fasteners leading to a rapid loss of dimensional stability. Additionally, the use of some natural oils in wood coatings can contribute to the development of unsightly mould and fungal growth underneath subsequently applied coatings. This situation can be difficult and costly to fix.

CUTEK® Oil

=

TRUE PENETRATION AND MIGRATION WITH SELF HEALING

COMPETING NATURAL OILS / “PENETRATING OILS”

=

ENCAPSULATING COATING

NOTE: Coatings that are not permanently mobile inside the wood and do not exhibit the self-healing effect ARE NOT the same as CUTEK® no matter what is claimed. Just ask the precoaters who have been using CUTEK® for years. Our first priority is always to extend and maximise the service life of timber NOT to steer you into the ecosystem of our other products.

MACHINE FRIENDLY SOLUTION

CUTEK® oils are fast and easy to use in pre-oiling machines. CUTEK® oils are a very low maintenance machine solution with fast daily start-up and shutdown unlike many competitors’ products that require time consuming and product wasting cleaning procedures at the end of every run. Cleaning, if required, is simple and easy.

Wood freshly coated with CUTEK® oil can be installed straight away or block stacked wet for later use. That is faster turnaround times for you and your clients. CUTEK® oils can obtain incredibly high spreading rates without compromising efficacy leading to lower cost per lineal metre compared to many other applications on the market.

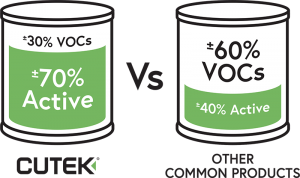

LOWER VOC LEVELS THAN MOST COMPETITOR OIL-BASED PRODUCTS

With CUTEK® more protective components penetrate and STAY permanently in the coated timber. A VOC number quantifies how many volatile organic compounds are released from a coating into the environment as it dries.

CUTEK® timber oils typically contain 20-30 % VOC’s whereas many competitor pre-oiling products contain VOC’s at the 50-60 % level (ASTM3960).

The use of lower VOC CUTEK® oils for pre-oiling means that exceptionally high spreading rates may be obtained without any compromise of product efficacy.

Generally speaking, when competing coatings are compared, a cheaper high VOC coating may become a more expensive option when compared to a lower VOC coating when the amount of product that ACTUALLY REMAINS ACTIVE IN THE COATED WOOD is calculated by subtracting the VOC content by volume of each product.